As pioneers in the field of special welding, we have established a competitive advantage that enables us to provide comprehensive services ranging from welding materials to construction.

TOKUDEN is engaged in business mainly related to overlay welding technology (welding technique to deposit metal onto the surface of machine parts made of either the same or different material) requiring special technology in metallic "surface modification" and in overlay welding materials. We boast top-class results as one of the only companies in Japan that can provide comprehensive services from the provision of welding materials to accepting orders for construction.

Business Divisions

We specialize in special welding related to special steel and non-ferrous metal and provide various welding materials and conduct welding construction that uses overlay welding technology with advanced abrasion, heat and corrosion resistance as the core technology.

We engage in distinctive welding construction work based on the keywords "special materials and abrasion resistance" that leverages our strengths as a welding material manufacturer.

As a company boasting special welding technology, TOKUDEN conducts welding related to a variety of production equipment, from the core industries of iron-making, petrochemicals and cement to the home electronics, automobile and the foodstuff industries. While there are countless welding contractors in Japan, from large to small companies, only several welding material manufacturers have entered the market for construction. TOKUDEN commands top market share among these companies.

We meet strong demand for the abrasion, corrosion and heat resistance required in production equipment and machines by way of technologies related to "special welding materials" that use special materials aside from mild steel and abrasion-resistant overlay welding that regenerates the worn part through overlay welding.

Type of Construction

Different types of welding work

Overlay welding for continuous casting machine roll

Overhaul work

Mantle core, eccentric bush

Our ability to minimize abrasion provides us with a competitive advantage and we have secured top share in flux-cored wires for submerged arc welding. We also boast the third-highest share in arc welding electrodes for hard facing.

The welding materials related to special steel and non-ferrous metal that we provide boast exceptional heat, corrosion and abrasion resistance as well as excellent welding properties. They are used in a wide range of fields, including the general manufacturing industry such as machinery, automobiles, construction equipment, chemistry and foodstuffs, and especially in areas requiring abrasion resistance such as charge chutes, conveyor belts, mixers, crushers, petrochemical valves and molds at iron foundries and cement works. Among our special welding materials, flux-cored wires and arc welding electrodes for hard facing boast a unique production system that handles high-mix, low-volume manufacturing and we have secured high market share in these sectors. Going forward, we seek to improve business performance by further differentiating ourselves and promoting joint development with our client companies.

Main Products

Flux-cored wires for submerged arc welding and MAG welding

Arc welding electrodes for hard facing

Wire rods for TIG welding

Wire rods for MIG welding

Agglomerated and fused fluxes

Powdered material for PTA welding, etc.

Advanced abrasion resistance and corrosion resistance coupled with a beautiful surface ensure differentiation from competition. We thus continue to command top share in the industry.

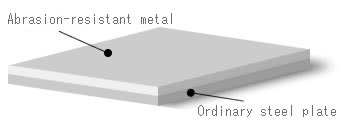

Of all abrasion-resistant clad steel plates (steel plate where an ultra-abrasion-resistant alloy is deposited onto a mild steel plate by means of special overlay welding), Top Plate realizes a beautiful surface, advanced hardness and minimal distortion with hardly any irregularities, thanks to a special production method. Compared with low-priced abrasion-resistant clad steel plates made overseas, this product has extremely high abrasion and corrosion resistance.

Top Plate is mainly used in iron foundries and cement works for parts such as charge chutes, hoppers, fans, cyclones, mixers and crushers that are subjected to abrasive wear by way of coke, raw materials and soil and stone. Going forward, we aim to maintain high profit by maximizing the competitive advantage as a high-quality product and meet diverse demand by means of a flexible production system.

Main Products

Top Plate

Pipes

Iron foundry

pressure-equalizing device

Trunnion journal

Chutes

We are strengthening initiatives to take advantage of growth markets such as environment-related equipment.

We provide products that anticipate the needs of the times, including environment-related equipment such as deodorizing devices that absorb offensive odors and purify the air in automobile manufacturing processes as well as forced-cooling apparatuses for casted automotive parts.

Moving ahead, we will utilize the technology and know-how we have accumulated in special welding particularly in the growing automotive industry and promote joint development with automakers in order to develop this sector into a new pillar aimed at enhancing business performance.

Main Products

Environment-related equipment: Deodorizing devices and forced-cooling apparatuses

Deodorizing device

Forced-cooling apparatus